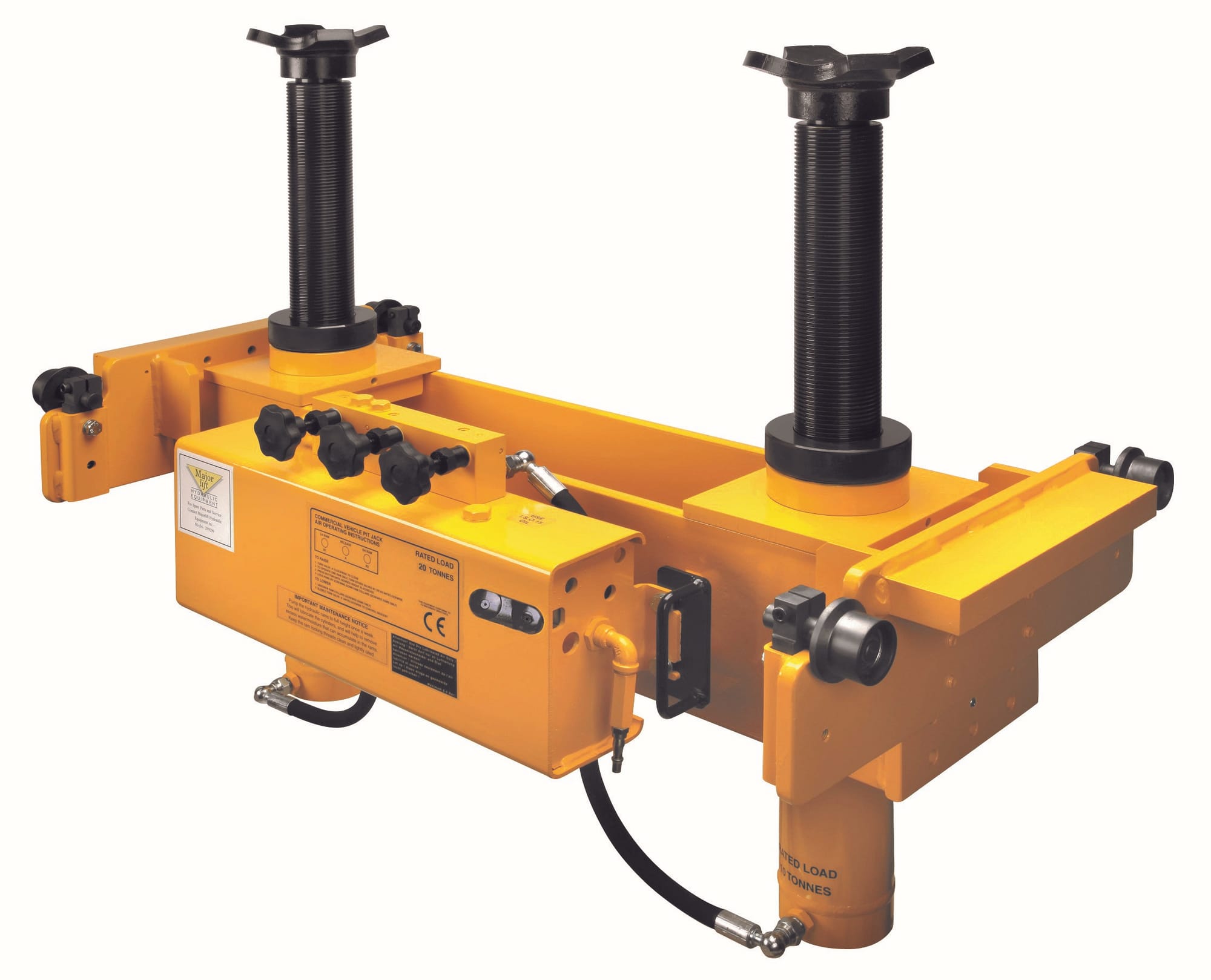

12 tonne Manual Hydraulic Jacking Beam

Majorlift Commercial jacking beams can be purchased for your Inspection Pit or Vehicle lift. They are rapid, reliable and rigorously safe and will tackle anything and everything up to 40 tonnes. Includes a 305mm lifting stroke, full lateral ram adjustment and high-safety twin ram system, all backed by proven hydraulics and positive mechanical safety locks.

- Brand: Majorlift

- SKU: HPJ12

- Shipping:

Product Description

AXGE Offer Price :

* * HPJ12. 12.0 tonne Manual Hydraulic Jacking Beam, £2,895.00 + vat (£3,474.00 inclusive)

NOTE :

Support Ends manufactured to fit your Inspection Pit or Vehicle Lift.

Choice of three different width Spreader Beams, 10 tonne capacity.

* * Includes direct delivery to your company premises and 20% vat.

* * Scottish Highlands & Islands may incur extra delivery costs, ring before you buy.

A VAT Invoice will be issued with your purchase.

NOTE OUR PRICING PROMISE BELOW.

MAJORLIFT - The perfect solution for lifting modern Commercials and HGV's.

Accessories Supplied as Standard

Commercial Pit Jack and Commercial Lift mounted jacking beams are supplied complete with a full set of slip-on adaptors to assist in jacking axles, diffs and chassis etc, they include:

2 x 4101 V head Height 165mm

2 x 4102 Dished head Height 89mm

2 x 4103 Chassis head Height 54mm

2 x 4105 Extension tube shoulder Height 152mm

Pit Mounted Commercial Jacks Standard Features.

Twin ram operation – Greater operational stability, efficiency and safety.

The rams slide transversely, making precise positioning under the vehicle possible, AND they can be used independently or in tandem, allowing one or both sides of the vehicle to be lifted.

Surface Engineered for a longer, harder working life – All key components in a Majorlift jack now have their working life greatly extended through a patented surface engineering process.

This range of treatments develop iron nitride surface compound layers to toughen the surface and resist rust. The nitrogen-enriched zone can improve yield and fatigue strengths by as much as three or fourfold.

Control valves as standard – Precise lowering for optimum safety and working conditions.

Pressure relief valve – Automatically prevents overloading.

Positive mechanical safety lock – Threaded rams and collars greatly enhance operator safety especially against accidental lowering.

Pumps can be either air-powered or hand-operated – Air-operated gives easy and rapid lift; hand gives easy double action pumping.

Quietest Ever Majorlift Pump – The new quieter design of Majorlift pump, built into every air jack – significantly enhances performance and reduces noise as well as further improving operational reliability.

Load bearing supports and spring loaded rollers – A long established Majorlift design for smooth, easy and safe movement along the pit.

- For lifting loaded tri-axle trailers, the 20-tonne model must be used.

- Custom-built beams for unusually shaped pits.

- Test certificates supplied with all beams.

Optional Accessories for consideration.

Spreader Beams (10 tonne capacity) Part No 4250 beam 830mm (31”) min pit width |  |

| Extension Tubes 4104 extension tubes shoulder height 100mm (4”) 4106 extension tubes shoulder height 250mm (10”) 4107 extension tubes shoulder height 450mm (18”) |  |

| Diff Beam Part No. 4500 Allows use of both rams to lift maximum loads at one point. Safe working load 20 tonnes. |  |

| Double extension top beam Part No 4600 Makes your commercial jacking beam suitable for servicing of cars and light vehicles or MOT Testing of Class 4 and Class 7 vehicles. |  |

| Storage Rack Part No. 2626 Keep all your accessories neatly in one place. |  |

Technical Spec HPJ12.

| Manually Operated Jacking Beam | RATED 12.0 TONNES |

|---|---|

| Part No. Manual | HPJ12 |

| Max lifting capacity | 12.0 tonnes |

| Overall Weight | 130 kgs |

| Air Pressure | N/A |

| Hydraulic Pressure | N/A |

| Ram(s) | 2 x 6 tonne each |

| Weight – with top beam | 224kgs – 494lbs |

WARRANTY 5 YEARS (Terms Apply)

Majorlift Guarantee

Majorlift guarantee their products to be free from defects due to faulty material or workmanship.

The period of the guarantee commences from the date of delivery to the purchaser, either by us or by our distributor as specified.

The prescribed maintenance schedule must be carried out in order to qualify for the 5-year term of the warranty; failure to do so will void the warranty term.

All maintenance must be recorded in order to support a claim if necessary.

All 5-year warranties must be registered with Majorlift by completing the warranty registration card.

Full Warranty Terms and Conditions, on request.

Pricing Promise :

We promise never to be beaten on price by our competitors, if you see a price advertised cheaper than us, we will match it for you, no problem!

We simply need to ensure the item you have seen is identical to ours and in stock, then we are good to go.

Please Note : All Pricing on our Website includes 20% vat.