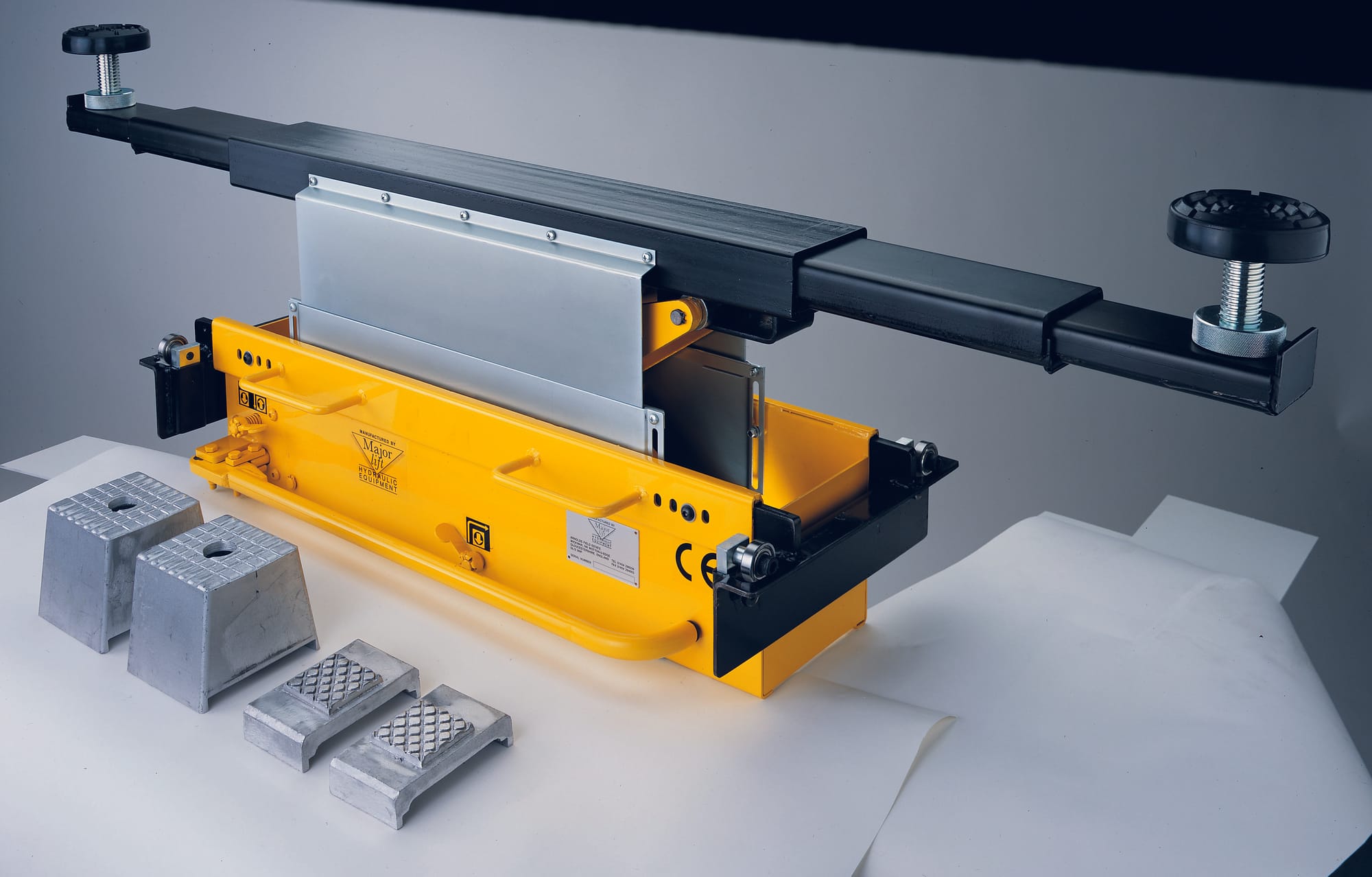

2.0 tonne Air Hydraulic Operated Jacking Beam

With its robust construction and easy-to-use air hydraulic operation, the Majorlift MPJ2.0EW extra wide, 2 tonne capacity jacking beam is an essential addition to any automotive workshop. If you want to safely carry out Class 4 MOT testing, lift electric vehicles, service & repair cars and vans, this is the jacking beam for you.

- Brand: Majorlift

- SKU: MPJ2.0EW

- Shipping:

Product Description

AXGE Offer Price :

* * MPJ2.0EW, 2.0 tonne Air Hydraulic jacking beam, £1,600.00 + vat (£1,920.00 inclusive)

Fitted with basic flat or hook type roller support arms 1333 or 1334?

NOTE :

Our jacking beams have standard support arms 1333 or 1334 , however you may require specific support arms to allow fitting to you MOT Testing Lift or Inspection Pit.

This OPTION will require extra cost, please contact us with four-post lift model/type prior to purchase .

** Includes direct delivery to your company premises and 20% vat.

** Scottish Highlands & Islands may incur extra delivery costs, ring before you buy.

A VAT Invoice will be issued with your purchase.

The Majorlift MPJ2.0EW (EW - Extra Wide top beam)

Supplied as standard with an extra-wide top beam of 1875mm fully extended.

NOTE OUR PRICING PROMISE BELOW.

The perfect solution to lifting modern vehicles including EVs

Due to recent advances by vehicle manufacturers, the design of modern cars, and particularly EV’s, have become lower and wider, with longer suspension travel.

All these changes have impacted on lifting equipment specifications, especially those of jacking beams.

To ensure Majorlift remains the number one choice in the UK they are now manufacturing updated 2t and 2.8t jacking beams with a huge 1875mm wide top beam as standard, all at no extra cost.

Supplied as standard with new style accessories :

– 2 x adjustable lift pads

– 2 x 70mm extensions

– 2 x 40mm rubber blocks

Further accessories and vehicle specific pads also available see below.

Majorlift Jacking Beam Standard Features

Top Beam

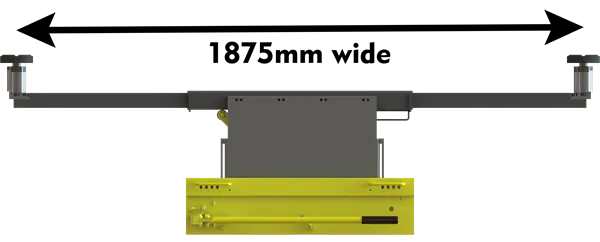

All 2 tonne models are fitted as standard with the NEW industry leading top beam that extends to an astonishing 1875mm to the centre of lifting pads, whilst still retracting to a mere 790mm.

Ram and Scissors

A full 260mm (10.25”) lift with proven hydraulics, the heart of every Majorlift jacking beam: gutsy, robust and very reliable.

Safety Features

Hose burst valve, pressure release valve prevents overloading, finger guard complies with European machinery directive and CE marking.

Quietest Ever Majorlift Pump

The new quieter design of Majorlift pump, built into every air jack – significantly enhances performance and reduces noise as well as further improving operational reliability.

Three-Position Mechanical Lock

Engages automatically creating safe working platform when carrying out extensive wheel overhauls.

Raiser Blocks

Supplied as standard with each beam. Rubber-topped screw pad (280019) and 70mm aluminium extension (280013) both locate into outer top beam, and 40mm rubber blocks (1590S) which will fit anywhere over the length of the centre section. Additional blocks and extensions can be supplied.

Support Arms

Easy roll operation from quality roller bearings – minimum effort, easy movement.

Roller Hook or Roller Flat Support Arms Supplied As Standard

Majorlift also fit support-arms (extra P.O.A) to accommodate most makes of lift including Bradbury, Tecalemit, Werther, Stertil-Koni, Stenhoj, Laycock, Hofmann, Liftmaster, Snap On, Boston, Dama, SLIFT, Ravaglioli, Nussbaum, Consul, Rotary, Maha, Cascos, Omer, Texo and Wheeltronics.

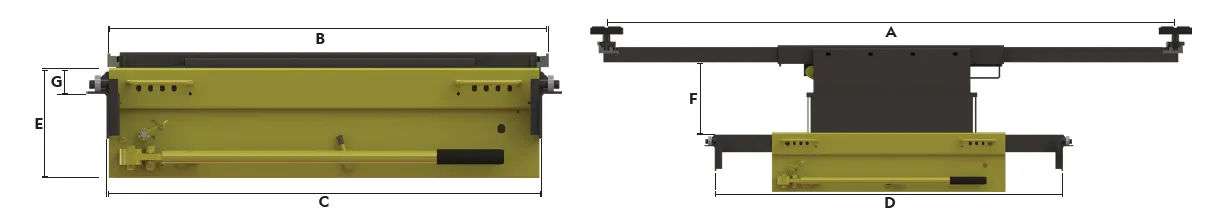

Dimensions of the Majorlift MPJ2.0EW

Dimensions of the Majorlift MPJ2.0EW

| OPERATION - BY AIR HYDRAULIC PUMP | RATED 2 TONNES |

|---|---|

| MOT Approval for | Class 4 |

| Part No. Manual | MPJ2.0EW |

| A Width when extended | 1875mm – 74″ |

| B Width when retracted | 790mm – 31″ |

| C Minimum width over support arms | 775mm – 30.5″ |

| D Maximum width over support arms | 1125mm – 44.5″ |

| E Closed height | 212mm – 8.25″ |

| F Total lift | 260mm – 10.25″ |

| *G Height above platform/floor *can be set lower with special arms if required | 75mm – 2.9″ |

| Weight – with top beam | 97kgs – 214lbs |

Note : Narrow Jacking Beams available to Order.

To fit narrow pits and lifts (with the pump mounted externally)

| C Minimum width over support arms | 685mm – 27″ |

| D Maximum width over support arms | 1015mm – 40″ |

Selection of Accessories :

| Raiser Blocks Part No. 1526 Short (25mm high) and Part No. 1527 Tall (95mm high) aluminium to fit 2 and 2.8 tonne beam. Can be used alone or in conjuction with 1532A, particularly useful when lifting light vans or off road vehicles. |  |

Universal Raiser Blocks – ‘fits all makes of beam’Polyurethane, rigid core and soft non-slip exterior which moulds to the car underbody. Light, strong, safe and easy to use.

A set of the three part numbers above can be purchased using Part No. 1590 |  |

Extension Tube.180mm extension tube. Part Number – 280016 |  |

Extension Tube.38mm extension tube. Part Number – 280015 |  |

| Part No. 1532C to fit all scissor beams. Extra high 180mm / 7″ extensions – specially designed to facilitate safe lifting of vehicles with high axles and lifting points. Mainly high 4 wheel drive off road vehicles. Using this extension Part No. 1532C together with lifting pad Part No. 1532A (supplied standard on all scissor beams) a lifting height of 485mm / 19″ can be achieved. Replacements available for lift pad assembly Part No. 1532A and rubbber pad Part No. 15324. Part No. 1532V threaded V crutch – fits all scissor beams and can be used by itself or in conjunction with 1527 or 1532C. |   |

We offer these jacking beams as standard in our own Class 4 & 7 MOT Packages.

2 tonne model.

2 tonne model.

WARRANTY 5 YEARS (Terms Apply)

Majorlift Guarantee

Majorlift guarantee their products to be free from defects due to faulty material or workmanship.

The period of the guarantee commences from the date of delivery to the purchaser, either by us or by our distributor as specified.

The prescribed maintenance schedule must be carried out in order to qualify for the 5-year term of the warranty; failure to do so will void the warranty term.

All maintenance must be recorded in order to support a claim if necessary.

All 5-year warranties must be registered with Majorlift by completing the warranty registration card.

Full Warranty Terms and Conditions, on request.

Pricing Promise :

We promise never to be beaten on price by our competitors, if you see a price advertised cheaper than us, we will match it for you, no problem!

We simply need to ensure the item you have seen is identical to ours and in stock, then we are good to go.

Please Note : All Pricing on our Website includes 20% vat.