Inspection Pits

Our Inspection Pits are designed to provide a safe and efficient solution for conducting underside inspections of vehicles and equipment.

- Brand: AXGE

Product Description

Another Inspection Pit, ready for delivery.

For most of us when we see our first inspection pit it's already installed in the workshop floor.

The old style, manufactured with concrete blocks or bricks, filthy dirty, wet and with some sort of makeshift steps to gain entry to it? On top of that lead light cables, extension leads and air supply hoses disappear into the pit like strands of spaghetti!!!

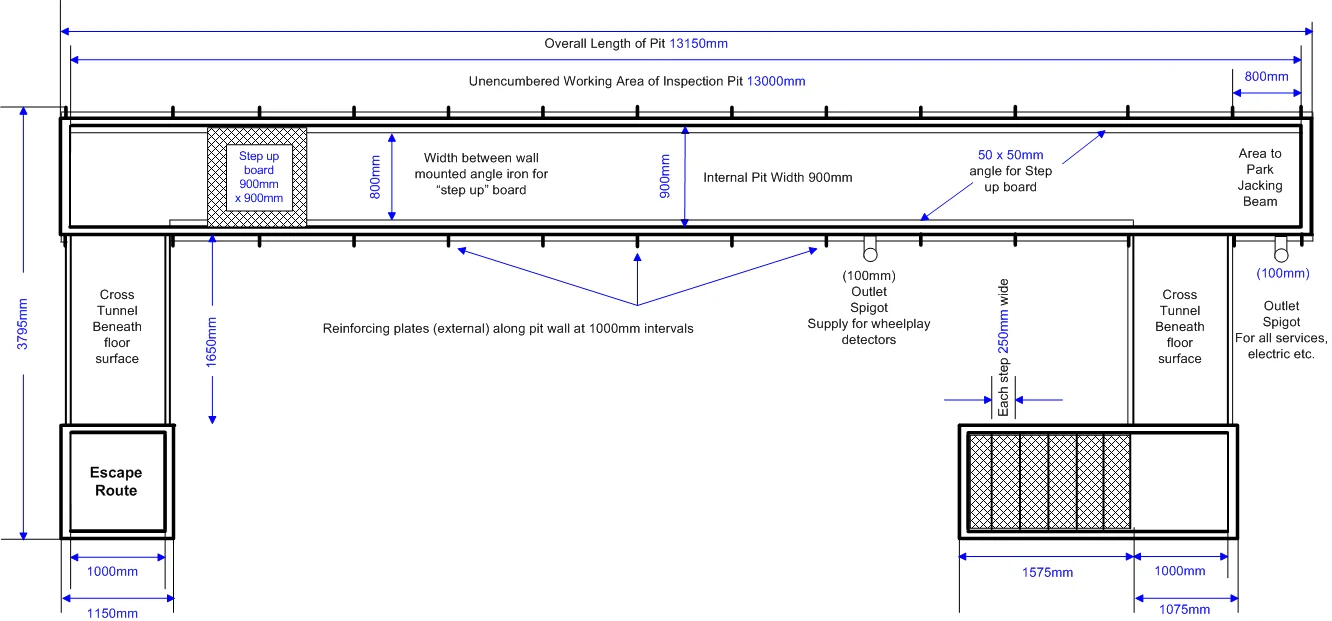

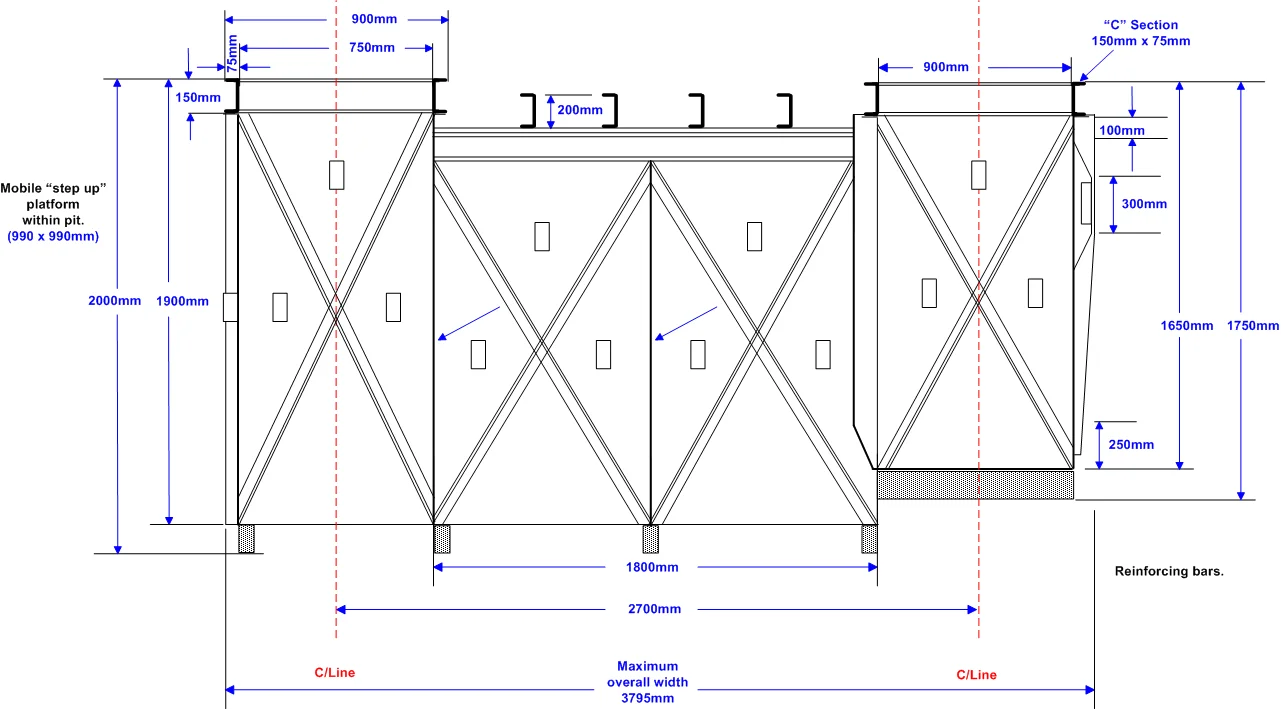

Forget all that and look at the Inspection Pits AXGE supply, they are completely the opposite, manufactured in "one-piece" (depending on design & dimensions) using 5mm thick steel with bright white gloss finish internal walls, walk-in removable steel staircase, a sump for any spillage, compressed air-lines, low voltage power supply and bright LED low-voltage lighting.

Utilities such as lighting and a high pressure airline are all pre-mounted into a pre-fabricated recess into the wall, allowing a clear working area for the technician.

This simple design eliminates accidental oil and grease spillages from sticking onto the lighting giving the pit a clean bright working environment always.

All our inspection pits are manufactured and fully marked to the standard :

BS EN 1090-2:2008 + A1:2011 Exc 2.

We are not restricted to inspection pits only.

If its made of steel and you have the dimensions of what you want we can quote you for it, we have supplied wash pits, cattle watering tubs, chemical dips, cattle crossing tubs etc, etc.

Prefabricated installation box for your roller brake tester.

If youre fitting a roller brake tester at the same time, why not save time on your installation costs and order a pre-fabricated metal installation cassette and save any possibility of a mistake being made.

Having supplied the motor trade for many years, our biggest business is workshop pits for everyday use, including bespoke size Servicing pits, MOT Testing Pits for all Classes and the very popular pit for the HGV ATF Testing Lanes. (Approved specification for DVSA use).

ATF Commercial Vehicle inspection pit for testing HGV's (smallest model)

Lets us help you with your needs, we can advise and offer the following services :

- Site meetings with surveys and advice

- Design and manufacturing of the inspection pit.

- Design and manufacturing of any associated equipment such as cassettes for roller brake tester, play detectors or radius plates etc, etc.

- Marking out your site ready for the builders excavation.

- Installation or overseeing of installation by customers civil engineers if required.

- Pre-installation of services including air extraction, electric lighting, sockets etc, etc.

- Supply of handrails, inspection pit covers, work-bridges etc, if required.

Once the detail has been agreed with client and approved by the DVSA, manufacture of the inspection pit can commence.

|

| |

|

| |

|

13m ATF Lane pit, nearly ready for paint |

13m ATF Lane pit, nearly ready for paint |

|

Collection by you or delivery to site, by flatbed or truck with HIAB.

Lowering into position at site (if pre-arranged)

Pit in position, levelling to proposed workshop floor.

Some other designs and installations.

Complex designs mean complex installation.

Simple Class 7 MOT Lane with pre-fabricated roller brake tester installation.

Easy access via side installation staircase and tunnel.

Once finished, you can work on the workshops final appearance.

Laser cut all steel panels

Laser cut all steel panels Ensure all welds are to standard

Ensure all welds are to standard  All sections are ribbed with reinforcement

All sections are ribbed with reinforcement All sections are ribbed with reinforcement

All sections are ribbed with reinforcement Service tunnel steps left, inspection pit right

Service tunnel steps left, inspection pit right

Manufacturer supplied wheel-play detector boxes ready for connection to pit

Manufacturer supplied wheel-play detector boxes ready for connection to pit