AXGE Class 7 MOT Test Lane

AXGE have been supplying workshops with MOT testing equipment since 1992. Today we still have many of those original bays working from the same premises. We can supply a full MOT Package or just a replacement item such as the lift or the brake tester, more recently "connected brake testers" have been amongst our best sellers.

- Brand: AXGE

- SKU: Class 4 MOT Bay

- Shipping:

Product Description

The Multitune MOT Bay is a Class 4 ATL (Automated Test Lane) package which includes as standard :

1 x VTEQ Laser Headlamp aligner and Rail set.

1 x VTEQ/Rotary Four Post 4000kg Lift, with 4700mm length platforms. The platforms on this lift are fitted with recessed Heavy Duty turning plates and recessed Heavy Duty hydraulic wheel-play detectors with wireless remote controlled handset and torch.

1 x VTEQ/ACH Jacking Beam 2000kg capacity and supplied a selection of lifting adapters.

1 x VTEQ3000 Roller Brake Tester complete with "in-car" tablet, remote control handset, and sturdy steel cabinet housing the PC, Windows 10 software, printer and monitor. Overall Specification :

| Size 2.920 x 680 x 280 mm | Track width 860 - 2.800 mm |

| Max. axle weight 4.000 Kg | Rollers size 990 x 206 mm |

| Rollers separation 400 mm | Test speed 5,4 Km/h |

| Friction coefficient Dry > 0,8 | Friction Coefficient > Humid 0,6 |

| Motors 2 x 5,5 kW (3ph) | Measurement range 0 ÷ 12 kN |

| Power supply 3 x 400V 50 / 60 Hz | Working conditions Temp -5 ÷ +40 ºC |

1 x Premier/Combi Wireless diesel smoke-head and emission tester, housed in a portable trolley with PC, Printer, monitor, keyboard, etc, etc.

2 x Wall or floor mounted mirrors

1 x Ancillary package comprising of :

- Latest "Connectable" Tapley Decelerometer/Brake Test Meter approved as an MTS device

- 13 pin tow bar socket tester

- Sign pack including : 1 x Testing Station 3 Triangles . 2 x MOT Parking . 1 x MOT Viewing Area . 1 x MOT Viewing Area Available

Class 7 Roller set with DVSA approval

Stylish cabinet (choice of colors) for control gear and the PC

Windows 10 Micro PC with keyboard & mouse

Twin Ethernet boards for direct internet connection

Latest Windows & VTEQ operating system

22” colour TFT Screen

Remote control

10" In-Car tablet display

6 tonne capacity fully galvanised heavy duty frame

Long life roller surface

Motor speed sensors

2 x 5.5 kW "Soft start motors"

Bi-Directional operation

4 Wheel Drive drive testing

Includes roller cover plates

All VTEQ brake roller sets are built utilising a very strong durable steel frame, hard wearing roller surfaces ensuring long life, something you would expect from a leading brand. Standard models include soft start and bi-directional motors with 4 Wheel Drive testing, remote control, in-car tablet and roller cover plates. Soft start rollers are used to remove the jerking action caused when brake rollers start initially. All VTEQ RBT's are now prepared for the DVSA Connectivity requirements and have intelligent software that enable the results to be forwarded to the DVSA website when requested. In addition VTEQ rollers can be configured to run dual software with your choice of emission tester, reducing equipment clutter and saving on costs. Available in various set-ups of hardware to ensure fitting can be achieved in your MOT BAY with the options of slim cabinets or pedestals etc, etc.

Fully DVSA Approved for use in all UK Testing Stations (Class 4, 5 & 7)

This machine can be supplied for use with Class 1 & 2 testing if desired.

Quite simply by adding software and a motorcycle cover plate for the roller bed.

Overall Specification :

| Size 2.920 x 680 x 280 mm | Track width 860 - 2.800 mm |

| Max. axle weight 4.000 Kg | Rollers size 990 x 206 mm |

| Rollers separation 400 mm | Test speed 5,4 Km/h |

| Friction coefficient Dry > 0,8 | Friction Coefficient > Humid 0,6 |

| Motors 2 x 5,5 kW (3ph) | Measurement range 0 ÷ 12 kN |

| Power supply 3 x 400V 50 / 60 Hz | Working conditions Temp -5 ÷ +40 ºC |

Looking towards the future :

The VTEQ range of Roller Brake Testers are fully expandable?

All VTEQ Roller Brake Testers can be upgraded to support a Suspension Tester and a side slip tester for use in a fully automated Test Lane as seen across Europe. Software is already included so only the hardware needs to be added if required.

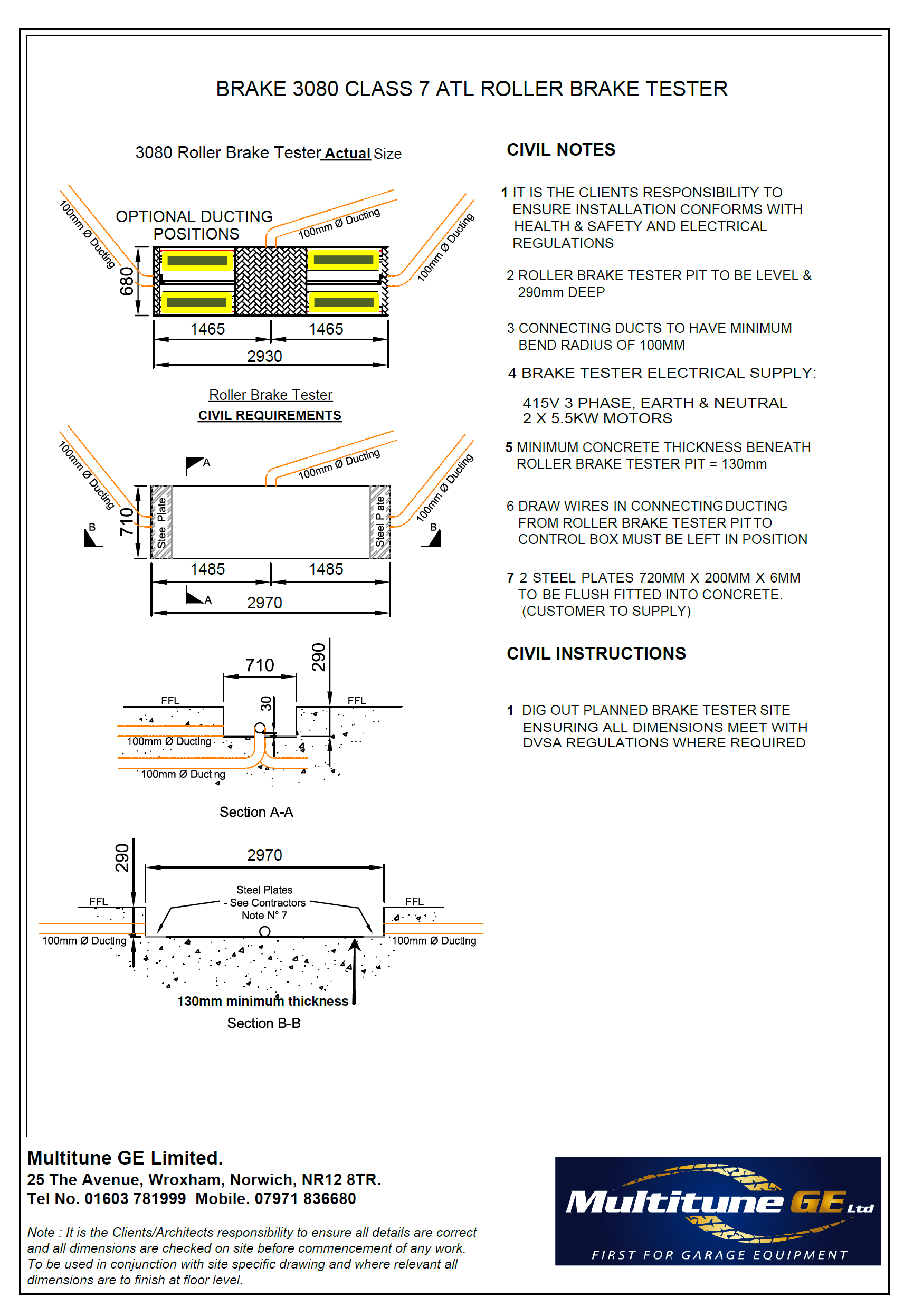

Installation details for Workshop floor :

Contact us for a drawing.

Optional Steel Cassette for simple installation by customer or builder :

If you want want minimal downtime and don't want delays due to the building works required?

Why not buy a steel cassette, simply remove old brake tester, cut out the concrete floor and lower in the

one-piece steel cassette, works could be done over a weekend.